Conduit run routes adapt to the building’s shape and layout. When obstacles like walls or beams are encountered, the conduit must be bent at specific angles. While conduit bends can technically be made at nearly any angle, not all are practical or preferred in the field. For this reason, ACP prioritizes standard bend angles whenever possible to promote efficiency, consistency, and alignment with industry best practices.

This article outlines the most commonly used bend angles and the typical scenarios where each is applicable.

Standard bend angles

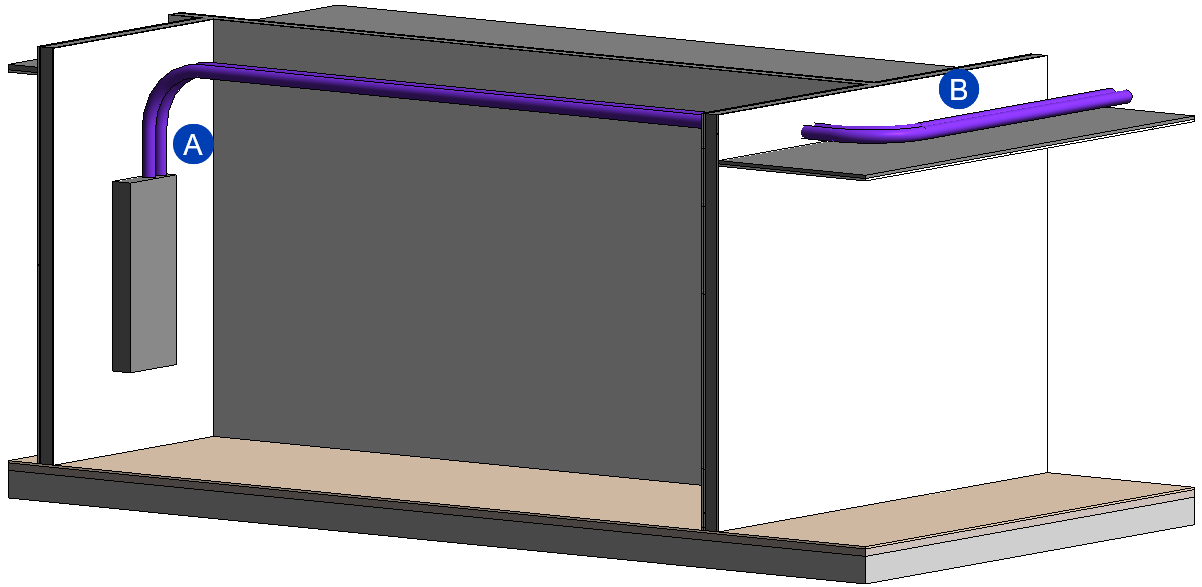

Most of the time, conduit direction changes will occur with a full 90° angle, either  to transition between horizontal and vertical orientations, or

to transition between horizontal and vertical orientations, or  to follow the natural turn of a wall.

to follow the natural turn of a wall.

In circumstances where a full 90° bend is not the most desirable option, ACP selects alternative standard bend angles to better suit the routing needs.

Hierarchy of standard bend angle selection

ACP prioritizes a 30° bend for non-90° angles. If a 30° bend isn't feasible in a given situation, the system will evaluate other standard bend angles one at a time until it finds one which works.

Below is the order of preference ACP follows when selecting standard bend angles for conduit routing solutions:

30° - Preferred, always tried first.

45°

60°

22.5°

15°

11.25°

10°

Offset bends

When a Rack conduits requires multiple offsets, all of the bends will use the same angle. The center of any diagonal segments will also be aligned to the same plane for consistency and ease of installation.

Here are some instances when offset bends will be used:

A horizontal rack needs to change elevation.

.png)

Vertical runs need to change planes.

.png)

A rack changes orientation due to a change in support style, i.e., Wall Support changing to a Trapeze Support

.png)

A rack changes configuration

.png)

A single conduit in a rack must be temporarily elevated to avoid a collision

.png)

Kick-90 bends

A single kick-90 bend consists of a 90° elbow and another elbow at a different angle. When multiple Kick-90s are run in the same rack, all secondary angles of a Kick-90 bend will be the same whenever possible, chosen according to the order of preference described above. Here are some instances when ACP will route conduits using a Kick-90 bend.

A horizontal rack uses a Kick-90 in order to change both elevation and direction.

.png)

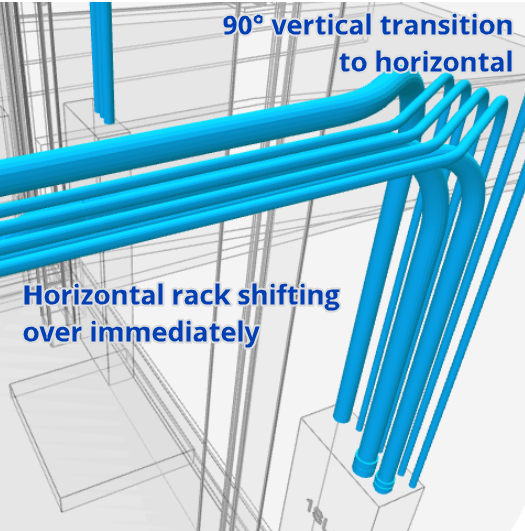

A vertical rack transitions to horizontal while maintaining direction, but the rack shifts slightly to the left or right.

A rack makes a 90° turn to transition to a horizontal run and rotates onto its side.

.png)

Non-Standard bend angles

While ACP will prioritize the standard bend angles in most of the routing scenarios, certain routing conditions may require the use of a non-standard bend angle.

This typically occurs in one of two circumstances:

No standard angle fits the routing requirements

Transitioning to/from Off-Axis areas

Standard Angles are inapplicable

When physical constraints like tight spaces or complex geometry prevent the use of standard bend angles, a non-standard bend will be applied. This ensures conduit routing remains optimal, clearances are maintained, and the design intent is preserved.

A similar scenario can occur with Kick-90 bends when a standard angle cannot be used for the secondary bend. In these cases, the shortest Kick-90 bend is prioritized, and its secondary angle is calculated to ensure all Kick-90 origins are aligned and maintain a perpendicular orientation to the rack. Any additional Kick-90 bends may use custom angles, which are calculated to preserve alignment and orientation throughout the routing.

Transitioning to/from off-axis areas

When the conduit route moves into or out of an off-axis area, a non-standard bend angle may be required to transition cleanly. In these cases, the bend angle is not selected from standard options but is instead determined directly by the angle of the off-axis geometry itself. For example, if a building section turns 42 degrees, a 42-degree bend will be used to match it exactly.

For more information on working with off-axis geometry, refer to the Managing off-axis areas article.

.png)